A Rare Engineering Tool

Challenge : to recreate an engineering tool that was too small to be recreated.

Technology used: 3D Scanning + Reverse Engineering

Inspection Software: GOM- Inspect

Duration: 3 Days

We have just got this challenging question solved on a positive note. One of our clients needed to recreate an engineering tool that was too small to be recreated using the traditional reverse engineering technique.

They have already done redesigning of the model but they were facing issues with accuracy final output wasn’t matching with the actual model.

Developing the prototype

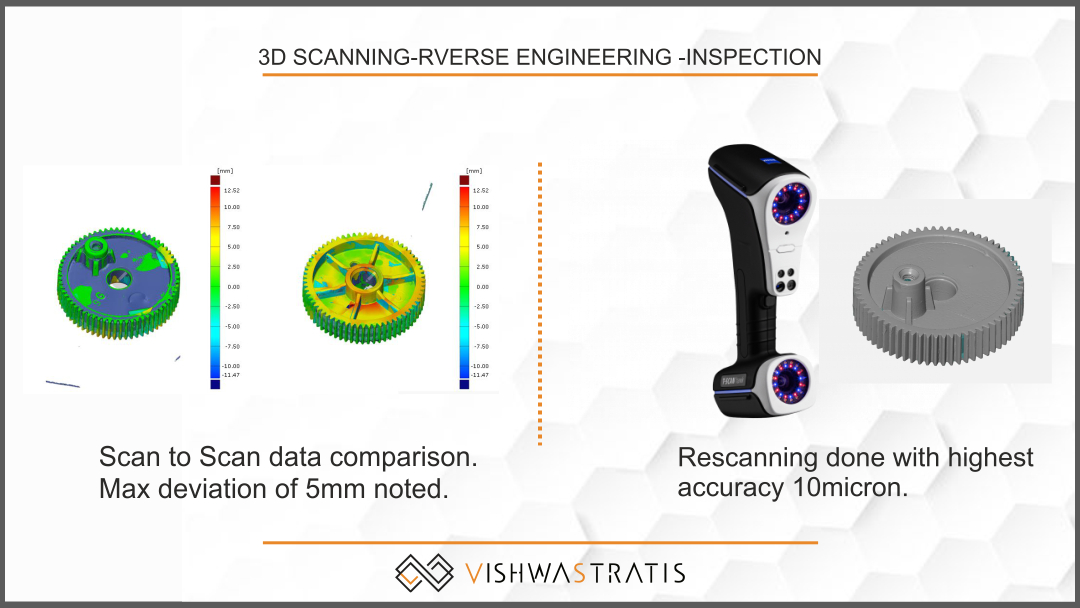

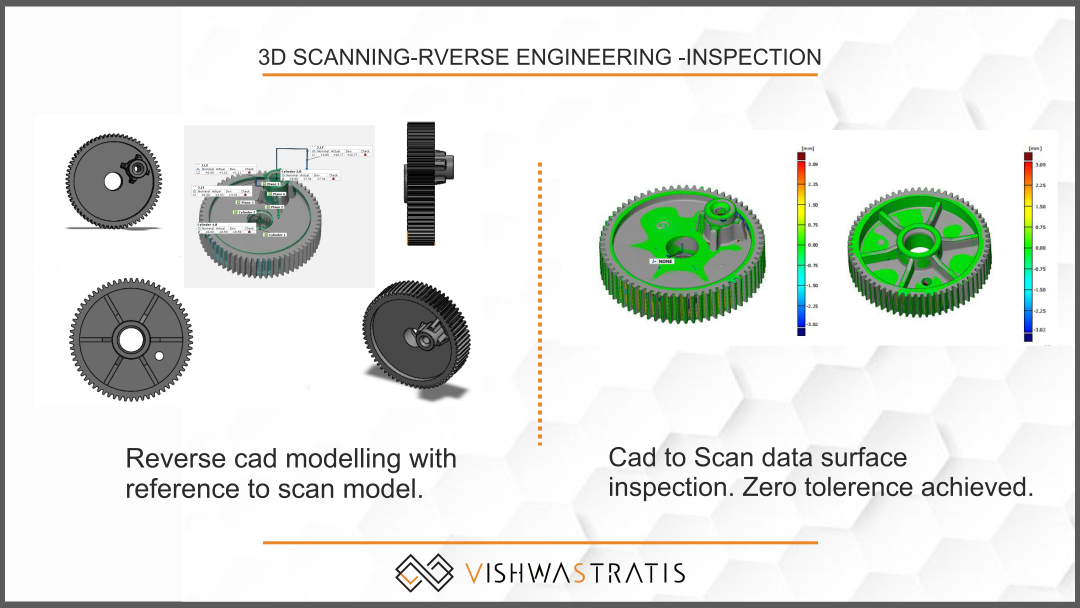

We accepted the project and gave them a solution with zero tolerance variation. While comparing their data we get to know that there was a 2.5 MM deviation in their data compared to the actual part. Which is huge!

We solved the problem following this process:

We scanned the part with our Zeiss T-Scan hawk scanner and Reverse Designed the model. When we compared our remodelled CAD file with the final output of scanned data, it was zero surface deviation! That’s amazing. The clients were happy and satisfied with the project too.

It’s just about the right technology and the right technique. Trust our expert hands. We are happy to serve such a challenging task.

To reverse engineering or 3D Scanning Services for your part, get in touch with us at info@vishwastratis.com or direct message us to start your project today!