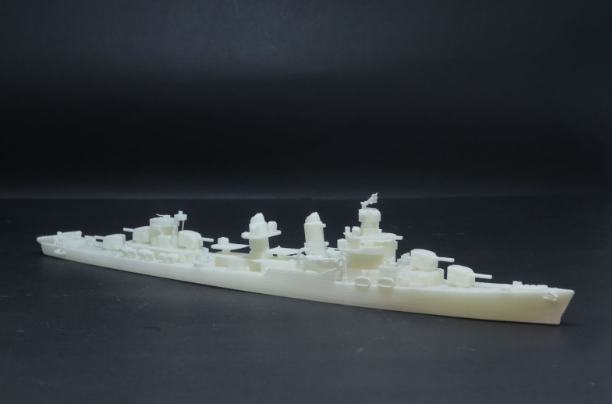

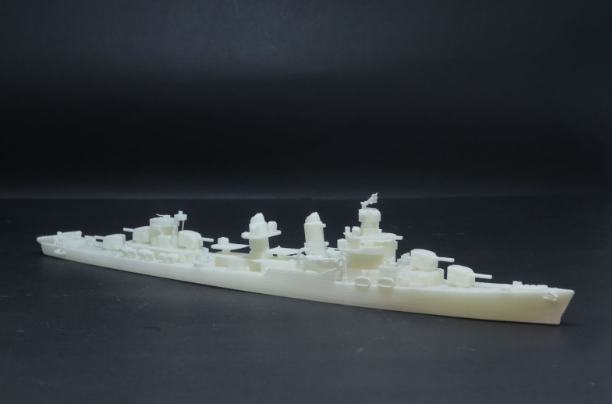

Create Complex Geometries With Superb Ease using SLS 3D Printing Service

Sls full form is Selective Laser Sintering, is a powder-based 3D printing service that produces sturdy and versatile end-use parts and objects using nylon.

Selective Laser Sintering (SLS) is a powder-based 3D printing technology, also known as SLS 3D printing, that uses nylon to create durable and versatile parts. The SLS 3D print process is ideal for both prototyping and low-volume production runs. One of the SLS uses is its ability to produce intricate geometries without the need for support structures, making it perfect for creating functional parts like interlocking components, moving parts, and living hinges. The selective laser sintering process offers unmatched design flexibility, allowing engineers to innovate without limitations.

Building on the capabilities of SLS 3D printing, the laser sintering process enables the production of highly accurate and durable parts with excellent surface finishes. Unlike selective laser melting, which fully melts the material, SLS sinters the powder, allowing for strong, functional components without the need for support structures. This flexibility in the SLS 3D print method makes it ideal for creating intricate designs, reducing material waste, and shortening production times, making it a preferred choice for industries looking for efficient and high-quality manufacturing solutions.