Diligence Clubbed with skills assures only excellence

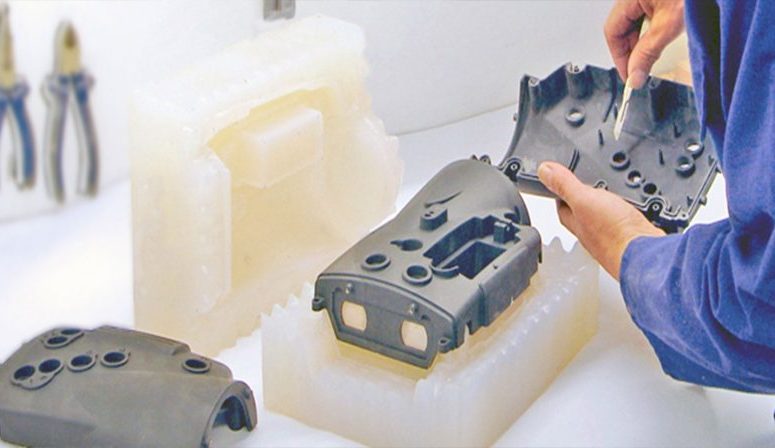

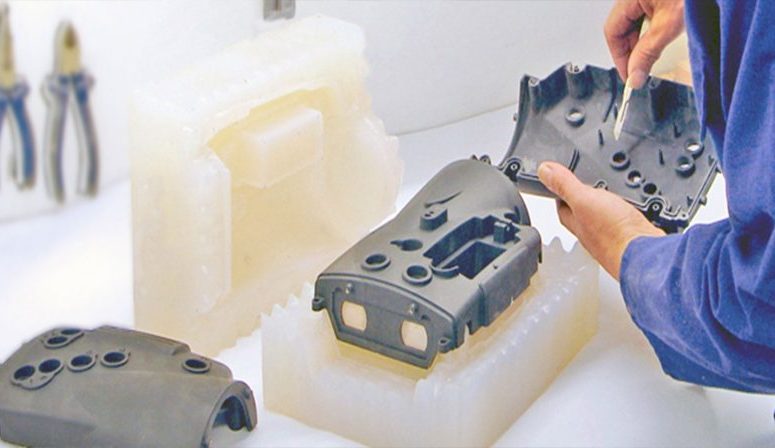

Vacuum Casting is extensively used to create functional prototypes for marketing and consumer testing or production parts for lower volume.It is ideal for businesses seeking vacuum casting services in India. The vacuum casting process, also known as v casting, is crucial for meeting diverse manufacturing needs efficiently.

At Vishwastratis, it’s all about innovation and precision. We employ our best tools to help you create what you want, in the most efficient and optimum manner. Vacuum casting services in Surat is one such service. It is an iteration technique used for producing samples or versions of functional plastic parts through the use of silicone molding. Its catch is the silky smooth, fine surface finish. The ability to cast complex shapes with thin walls through v casting enables us to make a quick, high-quality prototype or end-use product.

Bear lower costs and quick turnaround times.

Along with the economy of scales, manufacture parts in low volume from one to hundreds.

Along with the economy of scales, 3D product design enables us to manufacture parts in low volumes, from just one to hundreds.

Parts can be made in flexible or rigid plastics, and with vacuum forming, no post-processing or finishing is required.

When producing in batches, the vacuum casting process is crucial for realizing economies of scale

Vacuum Casting is one such service. It is an iteration technique used for producing samples or versions of functional prototypes for plastic parts, through the use of silicone molding. Its catch is the silky smooth, fine surface finish. The vacuum casting process allows us to cast complex shapes with thin walls, enabling us to make a quick, high-quality prototype or end-use product. These tests, be they mechanical or visual, often require vacuum casting services for functional prototypes without incurring a large cost and time delay.