Bringing imaginations to life

Enables to analyse and study a model without disassembling or destructing it. The scan data can be used to either replicate the part (Reverse-engineering) or for dimensional analysis (Inspection).

Vishwastratis is the ambitious expansion of Vishwa 3D, started by our director Mr. Brijesh Amin in 2013, standing tall by the adage of finding a better way to do everything. Our big powerhouse expanded their forces to utilise the synergy and create a one-stop-shop for all the 3d printing needs, in April 2020. Since then our passion for wielding the potential of next-gen technology is backing us in offering 360-degree solutions to all the prototyping needs.

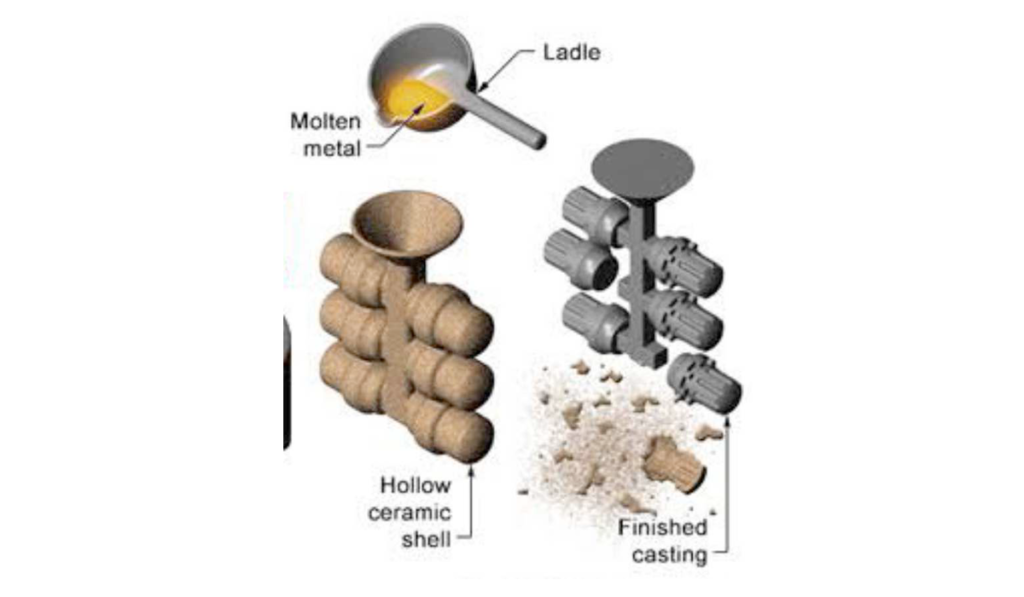

Although, mostly the investment castings are done for small products, it can produce castings weighing from tens to thousands of pounds.

It delivers consistent and repetitive close tolerances paired with intricate passages and contours. These configurations often births fine net-shape or near-net-shape casts.

The preciseness of the parts’ dimensional requirements are well replicated in this technique.

As a tried and tested technique for the design engineers, it has its own range of advantages.

investment casting is also known as lost-wax casting. In it the prototypes are created by pouring metal into the wax moulds which are later melted once the metal takes shape. It is simple, fast and cost-effective and is readily used technique. It is also put to use in the production of intricate and fine parts. As a tried and tested technique for the design engineers, it has its own range of advantages